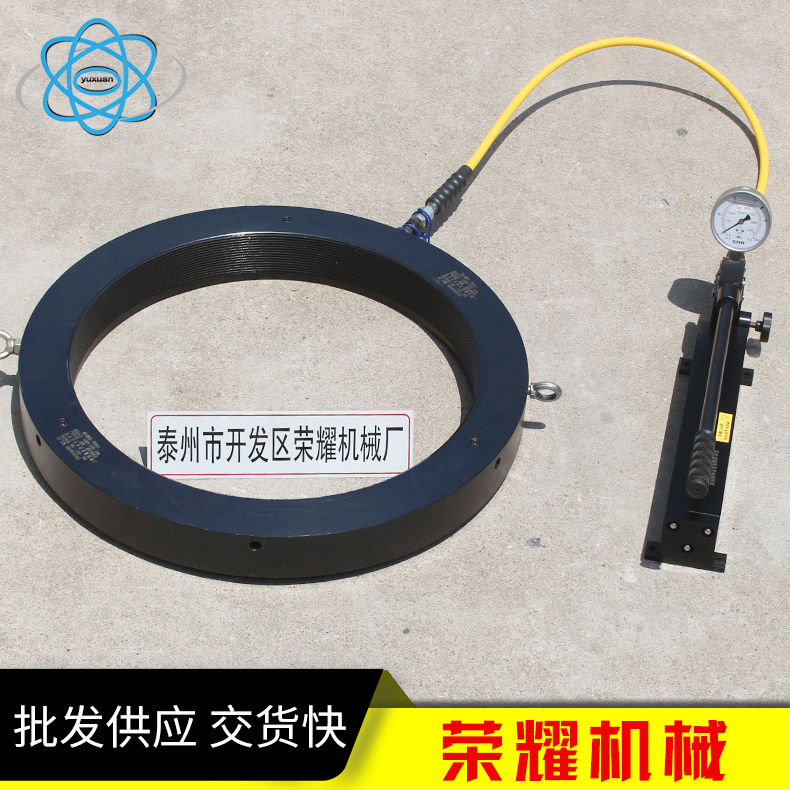

RYLM—液压螺母

一、概述

本厂生产的液压螺母是根椐多年来的生产实际经验,并结合一些使用厂家的要求开发、研制生产的成系列产品。该产品适用于需经常拆装的螺栓;螺栓的予紧;大型工件的锁紧等场合。并可做液压过盈连接拆装工具。

液压螺母的优点:操作方便、省力 ·予紧力大 ·可靠 ·可用于传统方法不能完成的地方。

基本参数(表中参数可能因为改良而变更,恕不另行通知)

|

型号 |

螺栓规格 |

外径 (mm) |

压 环 外 径 (mm) |

压 环 内 径 (mm) |

油 缸 厚 度 (mm) |

压 环 厚 度 (mm) |

行 程 (mm) |

最 大 推 力 KN |

重量 (kg) |

|

RYLM050 |

M50×1.5 |

50.5 |

104 |

114 |

38 |

4 |

5 |

290 |

2.70 |

|

RYLM055 |

M55×2 |

55.5 |

109 |

120 |

38 |

4 |

5 |

315 |

2.75 |

|

RYLM060 |

M60×2 |

60.5 |

115 |

125 |

38 |

5 |

5 |

330 |

2.80 |

|

RYLM065 |

M65×2 |

65.5 |

121 |

130 |

38 |

5 |

5 |

360 |

3.00 |

|

RYLM070 |

M70×2 |

70.5 |

127 |

135 |

38 |

5 |

5 |

380 |

3.20 |

|

RYLM075 |

M75×2 |

75.5 |

132 |

140 |

38 |

5 |

5 |

400 |

3.40 |

|

RYLM080 |

M80×2 |

80.5 |

137 |

146 |

38 |

5 |

5 |

420 |

3.70 |

|

RYLM085 |

M85×2 |

85.5 |

142 |

150 |

38 |

5 |

5 |

440 |

3.75 |

|

RYLM090 |

M90×2 |

90.5 |

147 |

156 |

38 |

5 |

5 |

470 |

4.00 |

|

RYLM095 |

M95×2 |

95.5 |

153 |

162 |

38 |

5 |

5 |

490 |

4.30 |

|

RYLM100 |

M100X2 |

100.5 |

158 |

166 |

38 |

6 |

5 |

510 |

4.40 |

|

RYLM105 |

M105×2 |

105.5 |

163 |

172 |

38 |

6 |

5 |

530 |

4.65 |

|

RYLM110 |

M110×2 |

110.5 |

169 |

178 |

38 |

6 |

5 |

560 |

4.95 |

|

RYLM115 |

M115×2 |

115.5 |

174 |

182 |

38 |

6 |

5 |

580 |

5.00 |

|

RYLM120 |

M120×2 |

120.5 |

179 |

188 |

38 |

6 |

5 |

600 |

5.25 |

|

RYLM125 |

M125×2 |

125.5 |

184 |

192 |

38 |

6 |

5 |

620 |

5.35 |

|

RYLM130 |

M130×2 |

130.5 |

190 |

198 |

38 |

6 |

5 |

640 |

5.65 |

|

RYLM135 |

M135×2 |

135.5 |

195 |

204 |

38 |

6 |

5 |

660 |

5.90 |

|

RYLM140 |

M140×2 |

140.5 |

200 |

208 |

38 |

7 |

5 |

680 |

6.00 |

|

RYLM145 |

M145×2 |

145.5 |

206 |

214 |

39 |

7 |

5 |

730 |

6.50 |

|

RYLM150 |

M150×2 |

150.5 |

211 |

220 |

39 |

7 |

5 |

750 |

6.60 |

|

RYLM155 |

M155×3 |

155.5 |

218 |

226 |

39 |

7 |

5 |

810 |

6.95 |

|

RYLM160 |

M160×3 |

160.5 |

224 |

232 |

40 |

7 |

6 |

860 |

7.60 |

|

RYLM165 |

M165×3 |

165.5 |

229 |

238 |

40 |

7 |

6 |

890 |

7.90 |

|

RYLM170 |

M170×3 |

170.5 |

235 |

244 |

41 |

7 |

6 |

940 |

8.40 |

|

RYLM180 |

M180×3 |

180.5 |

247 |

256 |

41 |

7 |

6 |

1030 |

9.15 |

|

RYLM190 |

M190×3 |

191 |

259 |

270 |

42 |

8 |

7 |

1150 |

10.5 |

|

RYLM200 |

M200×3 |

201 |

271 |

282 |

43 |

8 |

8 |

1250 |

11.5 |

|

RYLM205 |

Tr205×4 |

207 |

276 |

288 |

43 |

8 |

8 |

1280 |

12.0 |

|

RYLM210 |

Tr210×4 |

212 |

282 |

294 |

44 |

8 |

9 |

1340 |

12.5 |

|

RYLM215 |

Tr215x4 |

217 |

287 |

300 |

44 |

8 |

9 |

1370 |

13.0 |

|

RYLM220 |

Tr220x4 |

222 |

293 |

306 |

44 |

8 |

9 |

1440 |

13.5 |

|

RYLM225 |

Tr225x4 |

227 |

300 |

312 |

45 |

8 |

9 |

1520 |

14.5 |

|

RYLM230 |

Tr230x4 |

232 |

305 |

318 |

45 |

8 |

9 |

1550 |

14.5 |

|

RYLM235 |

Tr235x4 |

237 |

311 |

326 |

46 |

8 |

10 |

1620 |

16.0 |

|

RYLM240 |

Tr240x4 |

242 |

316 |

330 |

46 |

9 |

10 |

1650 |

16.0 |

|

RYLM250 |

Tr250x4 |

252 |

329 |

342 |

46 |

9 |

10 |

1760 |

17.5 |

|

RYLM260 |

Tr260x4 |

262 |

341 |

356 |

47 |

9 |

11 |

1880 |

19.0 |

|

RYLM270 |

Tr270x4 |

272 |

352 |

368 |

48 |

9 |

12 |

1980 |

20.5 |

|

RYLM280 |

Tr280x4 |

282 |

363 |

380 |

49 |

9 |

12 |

2110 |

22.0 |

|

RYLM290 |

Tr290x4 |

292 |

375 |

390 |

49 |

9 |

13 |

2240 |

22.5 |

|

RYLM300 |

Tr300x4 |

302 |

386 |

404 |

51 |

10 |

14 |

2360 |

25.5 |

|

RYLM310 |

Tr310x5 |

312 |

397 |

416 |

52 |

10 |

14 |

2490 |

27.0 |

|

RYLM320 |

Tr320x5 |

322 |

409 |

428 |

53 |

10 |

14 |

2630 |

29.5 |

|

RYLM330 |

Tr330x5 |

332 |

419 |

438 |

53 |

10 |

14 |

2700 |

30.0 |

|

RYLM340 |

Tr340x5 |

342 |

430 |

450 |

54 |

10 |

14 |

2840 |

31.5 |

|

RYLM345 |

Tr345x5 |

347 |

436 |

456 |

54 |

10 |

14 |

2940 |

32.5 |

|

RYLM350 |

Tr350x5 |

352 |

442 |

464 |

56 |

10 |

14 |

2990 |

35.0 |

|

RYLM360 |

Tr360x5 |

362 |

455 |

472 |

56 |

11 |

15 |

3130 |

35.5 |

|

RYLM365 |

Tr365x5 |

367 |

460 |

482 |

57 |

11 |

15 |

3170 |

38.5 |

|

RYLM370 |

Tr370x5 |

372 |

466 |

486 |

57 |

11 |

16 |

3280 |

39.0 |

|

RYLM380 |

Tr380x5 |

382 |

476 |

498 |

58 |

11 |

16 |

3350 |

40.5 |

|

RYLM385 |

Tr385x5 |

387 |

483 |

504 |

58 |

11 |

16 |

3470 |

41.0 |

|

RYLM400 |

Tr400x5 |

402 |

499 |

522 |

60 |

11 |

17 |

3670 |

45.5 |

|

RYLM410 |

Tr410x5 |

412 |

510 |

534 |

61 |

11 |

17 |

3830 |

48.0 |

|

RYLM420 |

Tr420x5 |

422 |

522 |

546 |

61 |

11 |

17 |

4000 |

50.0 |

|

RYLM430 |

Tr130x5 |

432 |

532 |

556 |

62 |

12 |

17 |

4080 |

52.5 |

|

RYLM440 |

Tr440x5 |

442 |

543 |

566 |

62 |

12 |

17 |

4250 |

54.0 |

|

RYLM450 |

Tr450x5 |

452 |

554 |

580 |

64 |

12 |

17 |

4410 |

57.5 |

|

RYLM460 |

Tr460x5 |

462 |

565 |

590 |

64 |

12 |

17 |

4510 |

60.0 |

|

RYLM470 |

Tr470x5 |

472 |

576 |

602 |

65 |

12 |

18 |

4690 |

62.0 |

|

RYLM480 |

Tr480x5 |

482 |

587 |

612 |

65 |

12 |

19 |

4860 |

63.0 |

|

RYLM490 |

Tr490x5 |

492 |

597 |

624 |

66 |

12 |

19 |

4950 |

66.0 |

|

RYLM500 |

Tr500x5 |

502 |

609 |

636 |

67 |

12 |

19 |

5150 |

70.0 |

|

RYLM510 |

Tr510x6 |

512 |

624 |

648 |

68 |

12 |

20 |

5330 |

74.0 |

|

RYLM520 |

Tr520x6 |

522 |

634 |

658 |

68 |

13 |

20 |

5430 |

75.0 |

|

RYLM530 |

Tr530x6 |

532 |

645 |

670 |

69 |

13 |

21 |

5620 |

79.0 |

|

RYLM540 |

Tr540x6 |

542 |

657 |

682 |

69 |

13 |

21 |

5820 |

81.0 |

|

RYLM550 |

Tr550x6 |

552 |

667 |

693 |

70 |

13 |

21 |

5920 |

84.0 |

|

RYLM560 |

Tr560x6 |

562 |

678 |

704 |

71 |

13 |

22 |

6120 |

88.0 |

|

RYLM570 |

Tr570x6 |

572 |

689 |

716 |

72 |

13 |

23 |

6320 |

91.0 |

|

RYLM580 |

Tr580x6 |

582 |

699 |

726 |

72 |

13 |

23 |

6420 |

94.0 |

|

RYLM600 |

Tr600x6 |

602 |

721 |

748 |

73 |

13 |

23 |

6730 |

100 |

|

RYLM630 |

Tr630x6 |

632 |

754 |

782 |

74 |

14 |

23 |

7290 |

110 |

|

RYLM650 |

Tr650x6 |

652 |

775 |

804 |

75 |

14 |

23 |

7620 |

115 |

|

RYLM670 |

Tr670x6 |

672 |

796 |

826 |

76 |

14 |

24 |

7950 |

120 |

|

RYLM690 |

Tr690x6 |

692 |

819 |

848 |

77 |

14 |

25 |

8420 |

127 |

|

RYLM710 |

Tr710x7 |

712 |

840 |

870 |

78 |

15 |

25 |

8770 |

135 |

|

RYLM750 |

Tr750x7 |

752 |

883 |

912 |

79 |

15 |

25 |

9520 |

146 |

|

RYLM800 |

Tr800x7 |

802 |

936 |

965 |

80 |

16 |

25 |

10390 |

161 |

|

RYLM850 |

Tr850x7 |

852 |

990 |

1020 |

83 |

16 |

26 |

11460 |

181 |

|

RYLM900 |

Tr900x7 |

902 |

1.043 |

1.075 |

86 |

14 |

30 |

12410 |

205 |

|

RYLM950 |

Tr950x8 |

952 |

1.097 |

1.126 |

86 |

17 |

30 |

13570 |

218 |

|

RYLM1000 |

Tr1000x8 |

1.002 |

1.15 |

1.18 |

88 |

17 |

34 |

14580 |

239 |

本厂也可根据用户要求设计、制造,以满足不同的螺纹规格及锁紧行程。

四、使用方法与注意事项

1.手动泵在使用前将液压油注满,注油口在手动泵的后端,打开螺母注油,注油后锁紧。加压时将泵上方的手柄上下压动,将泵右侧的卸荷开关手柄顺时针锁紧;卸压时将手柄逆时针旋转即可。左侧接压力表,可观察加压时的压力指示,手动泵前端接注油胶管。

2.液压螺母由螺母体、压环、注油口及放油排气接头组成,使用时将螺母外观清洗干净。螺母旋进工件并锁紧螺母,压环应在原始位置,然后将手动泵的注油胶管接口插在注油口上,锁紧手动泵右侧的卸荷开关手柄,慢慢加压,同时将放油排气接头上部的放气帽向内旋,放气,直至螺母内空气排净,流出干净的液压油后向外旋松放气帽使之单向阀关闭,继续加压注油,使压环向外压出,达到压紧目的,直到加压到你所需压紧目的即可。松开卸荷开关手柄,松开手动泵的加压胶管接头。

3.松卸螺母将放油排气接头向里旋转直至液压油流出,慢慢松开螺母即可。

4.螺母在没有旋进工件锁紧前,请不要给螺母加压,防止压环偏载脱出,在不使用时请将螺母内的油放净,压环回到原始位置,以备下次使用。在螺纹处加黄油防止生锈。